Hesco barriers are essential for providing protection in military and civilian applications. But have you ever wondered what they are filled with? The materials used for filling these barriers directly affect their effectiveness. In this article, we’ll discuss the primary materials used—sand, soil, gravel, and aggregates—and how they impact the performance of Hesco barriers.

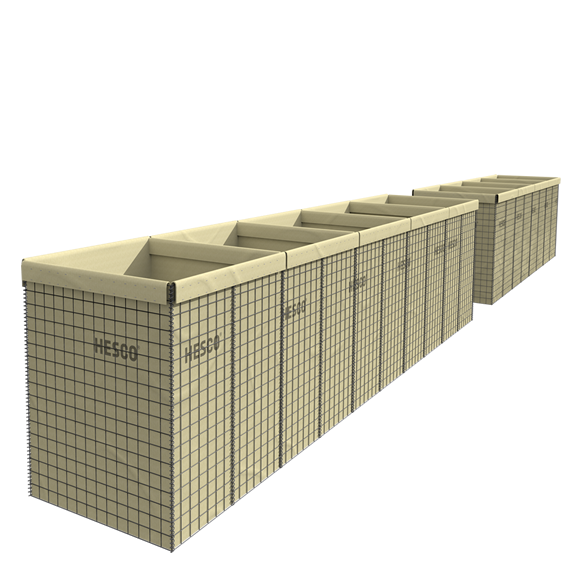

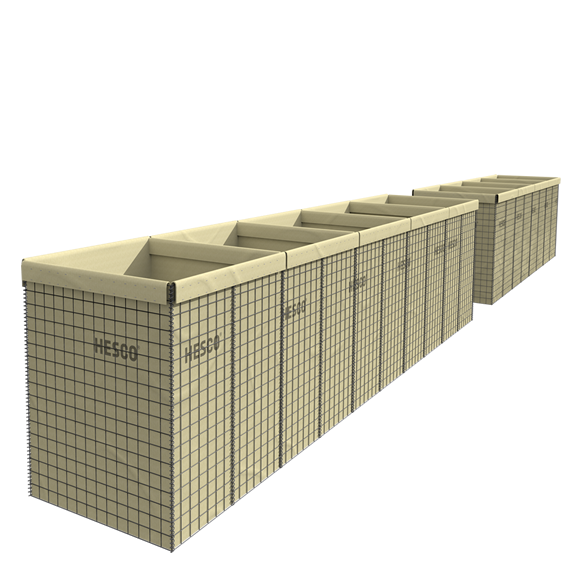

What Are Hesco Barriers?

Hesco barriers are collapsible wire mesh containers designed to offer protection against a variety of threats, such as blasts and small arms fire. These barriers are widely used for both military and civilian applications, providing a simple yet effective solution for creating protective barriers.

Common Uses of Hesco Barriers

Military Fortifications: They are often used in military camps, bunkers, and observation posts to safeguard personnel and equipment.

Flood Control: In areas prone to flooding, Hesco barriers are deployed quickly to form levees that help protect against rising waters.

Disaster Relief: After natural disasters, these barriers serve as temporary walls to protect critical infrastructure and create safe zones.

Structure of Hesco Barriers

Hesco barriers are built from welded wire mesh panels that form a collapsible frame. The wire mesh is coated to resist corrosion and ensure durability in tough environments. Inside the mesh, a heavy-duty fabric liner holds the fill material, which can be sand, soil, or gravel. This design provides flexibility, enabling quick deployment in various situations. These barriers are strong enough to withstand harsh conditions like small arms fire, shrapnel, and blasts, making them ideal for military use and emergency situations.

Material Composition:

Wire Mesh: Welded steel mesh, often coated with zinc for corrosion resistance.

Fabric Liner: Non-woven polypropylene, offering strength and UV resistance. Hesco barriers provide quick and effective protection, and their ability to be filled with local materials like sand or gravel makes them a practical choice in diverse environments.

What Materials Are Used to Fill Hesco Barriers?

1.Sand: The Most Common Fill Material

Sand is the most commonly used material for filling Hesco barriers, and it’s easy to see why. It compacts well and provides solid protection against blasts and projectiles. Its ability to absorb energy from explosions makes it highly effective in military and emergency applications.

Why Sand Is Preferred

Good Compaction: Sand packs tightly, offering stability to the structure.

Absorbs Impact: It helps reduce blast force, preventing damage to nearby areas.

Effective Protection: It stops small arms fire and shrapnel, making it perfect for defense.

How Sand Helps in Blast Protection

Sand absorbs the shock from explosions, dispersing the blast’s energy. This reduces the impact on surrounding areas and strengthens the barrier's resistance to further damage.

Common Uses for Sand-Filled Hesco Barriers

Military Camps: Ideal for fortifying bases, bunkers, and observation posts.

Emergency Defense: Quickly deployed in crisis situations to safeguard people and infrastructure.

Flood Defense: Used to build temporary levees during flooding events.

2.Soil: A Cost-Effective Alternative

When sand isn’t available or budget constraints are in play, soil is often used to fill Hesco barriers. It’s a cost-effective choice, especially in regions where sand and gravel are scarce or expensive.

Why Choose Soil?

Economical: Soil is generally more affordable than sand or gravel, making it a go-to option for budget-conscious projects.

Widely Available: It can be found locally, even in remote or rural locations, reducing transportation costs.

Benefits and Limitations of Soil-Filled Hesco Barriers

Benefits: Soil provides good protection, particularly in flood defense, by creating temporary barriers that can withstand moderate forces.

Limitations: While effective, soil doesn’t absorb blast energy as well as sand, so it may be less effective in high-impact situations.

Common Applications of Soil-Filled Hesco Barriers

Flood Defense: Soil is frequently used to construct temporary levees, protecting against rising water during floods.

Cost-Conscious Projects: Ideal when the cost of other materials like sand or gravel makes them impractical. Soil is an excellent solution when other fill materials are unavailable or too expensive, offering an affordable and effective alternative in many scenarios, particularly in flood control.

3.Gravel: Another Effective Fill Material

Gravel is another solid choice for filling Hesco barriers, offering excellent compaction and impact absorption. It’s a strong, durable material that works well in situations requiring a heavier fill.

Why Gravel Is Used

High Compaction: Gravel settles tightly within the wire mesh, creating a compact, sturdy barrier.

Impact Absorption: It helps to absorb blast forces and can withstand high-impact scenarios.

Sand vs. Gravel: Effectiveness and Cost

Effectiveness: Gravel performs better than sand when a more compact barrier is needed. It’s more effective in areas exposed to high blast forces.

Cost: While gravel may be slightly more expensive than sand, it’s often preferred for its superior protection and durability.

Common Use Cases for Gravel-Filled Hesco Barriers

High Blast Areas: Gravel is often chosen for areas where significant explosions are expected, as it offers better protection.

Where Sand and Soil Aren’t Ideal: Gravel is used when sand or soil doesn’t provide enough compaction or durability for the task at hand. Gravel is favored in situations that require a more compact, impact-resistant fill, making it an excellent choice for military defense or areas with high blast risk.

4.Other Aggregates: Exploring Alternative Fill Materials

While sand, soil, and gravel are common, other aggregates such as rocks and crushed stone can also be used to fill Hesco barriers. These materials are typically used in specific situations where sand or soil aren’t the best option.

Types of Aggregates Used

Rocks: Larger pieces of rock are sometimes used, providing high resistance to impact.

Crushed Stone: Smaller, angular stones can be used, offering compactness and durability.

When Are Aggregates Used?

Extreme Blast Protection: In situations where barriers must withstand high-intensity blasts, aggregates provide stronger, more durable protection.

Filling Large Areas Quickly: Aggregates like crushed stone are ideal for rapidly filling large volumes, especially when a fast solution is required.

Advantages and Drawbacks of Using Aggregates

Advantages:

Drawbacks:

Cost: Aggregates can be more expensive than sand or soil.

Availability: Not always locally available, especially in remote areas. Other aggregates are particularly valuable in specialized scenarios where high protection or rapid deployment is needed, but they come with considerations such as cost and availability.

How Are Hesco Barriers Filled?

Filling Hesco barriers is a straightforward yet efficient process, ensuring that the barriers are quickly ready to provide protection. Here's how it works:

Step-by-Step Process of Filling Hesco Barriers

Unfold the Barrier: Start by unfolding the wire mesh container, which expands into the desired shape.

Position the Barrier: Place the barrier where it is needed, whether for flood control, military defense, or another use.

Fill the Barrier: Use local materials, such as sand, gravel, or soil, to fill the barrier. The material should be evenly spread inside the mesh.

Compact the Fill: Ensure the material is compacted well to create a solid, stable structure.

The Role of Heavy Equipment

Heavy Machinery: Equipment like front-end loaders, TRAMs, and other heavy-duty machinery can quickly fill the Hesco barriers.

These machines scoop up the fill material and load it directly into the mesh containers.

Using heavy equipment can speed up the process by up to 10 times compared to manually filling sandbags, making it ideal for large-scale operations.

Manual Labor When Equipment Isn’t Available

Manual Labor: In situations where machinery is unavailable or in smaller-scale setups, workers use shovels and other tools to manually fill the barriers.

Although slower, this method is effective in emergency or remote locations where machinery cannot reach. Filling Hesco barriers can be done efficiently using heavy equipment, and even when machinery isn’t available, manual labor ensures the barriers are filled and deployed quickly.

What Factors Affect the Choice of Fill Material for Hesco Barriers?

Availability of Materials

The choice of fill material for Hesco barriers often depends on what’s available locally. For example, in remote areas or combat zones, materials like sand, gravel, or soil may be the easiest and quickest option to access.

Local Resources: Proximity to sand dunes, soil, or gravel pits can determine what materials are used.

Easy Access: In many cases, using local materials is more practical and efficient.

Cost Considerations

Cost plays a significant role when deciding on the fill material for Hesco barriers. Sand and soil are generally cheaper than other materials like gravel or crushed stone, making them more cost-effective options, especially for large-scale deployments.

Budget-Friendly: Soil and sand are often more affordable than specialized aggregates.

Cost Efficiency: In disaster relief or emergency defense, cost-effective options are essential for rapid deployment.

Environmental Conditions

Harsh weather and terrain conditions also influence the choice of fill material. Hesco barriers filled with sand, gravel, or soil perform differently depending on whether they are exposed to heavy rainfall, extreme temperatures, or rough terrain.

Weather Resistance: Some materials hold up better under wet or extreme conditions.

Terrain Suitability: In rocky or mountainous areas, gravel may be more appropriate than soil, which could wash away.

Local Material Accessibility

In certain situations, like in combat zones or flood-prone areas, local materials such as dirt and gravel are more accessible. These materials are often more readily available and easier to transport, especially when heavy machinery is involved.

On-Site Materials: In areas where transportation of materials is limited, using locally sourced dirt or gravel can reduce costs and speed up deployment.

Rapid Deployment: In emergency situations, using what's available nearby can be crucial. The choice of fill material for Hesco barriers is influenced by multiple factors, from material availability to environmental conditions, all of which must be considered for the most effective barrier setup.

Can Hesco Barriers Be Refilled?

Explanation of How Hesco Barriers Can Be Refilled After Use

Yes, Hesco barriers can be refilled after they have been used. Over time, these barriers may need to be replenished with new fill material to maintain their strength and effectiveness. This is particularly important if the barrier has been compromised by blasts, weather, or wear and tear.

Refilling Process and Materials Typically Used

The refilling process involves removing the old material and replacing it with new fill. Common materials used for refilling include:

Sand: Provides a solid, stable fill.

Gravel: Offers compactness and durability.

Soil: A cost-effective option for replenishment. Heavy equipment, like front-end loaders, is often used to fill Hesco barriers quickly, though manual labor can also be employed if machinery is unavailable.

Challenges in Refilling in Combat Zones or Emergency Situations

Refilling Hesco barriers in combat zones or emergency areas can be challenging. In these situations, it may be difficult to access the necessary materials or use heavy equipment due to ongoing threats or limited resources.

Limited Access: Difficulty in transporting materials to the site.

Security Concerns: Ongoing threats may prevent safe access to refilling areas. Despite these challenges, Hesco barriers are designed for easy maintenance and can be refilled either manually or with equipment, ensuring that they remain effective when needed the most.

Conclusion

Hesco barriers are filled with materials like sand, soil, gravel, and aggregates. The choice of fill depends on availability, cost, and specific needs. Sand is commonly used for its compaction and blast absorption, while soil offers a cost-effective option. Gravel is ideal for high-impact areas. Hesco barriers are versatile and used in both military and civilian applications, providing quick, effective protection. When choosing fill material, consider the situation—whether for military fortifications or flood control.

FAQ

Q1: What are the best materials for filling Hesco barriers?

A: The best materials include sand, soil, and gravel. Sand is often preferred for its impact absorption, while soil is more cost-effective and readily available in some regions. Gravel offers similar benefits to sand in terms of compaction.

Q2: Can I refill a Hesco barrier after it's been used?

A: Yes, Hesco barriers can be refilled using sand, soil, or gravel. The refilling process is often done with heavy equipment but can also be done manually when needed.

Q3: How long do Hesco barriers last?

A: Hesco barriers typically last several years depending on the quality of mater